Armada for IBM® Maximo®

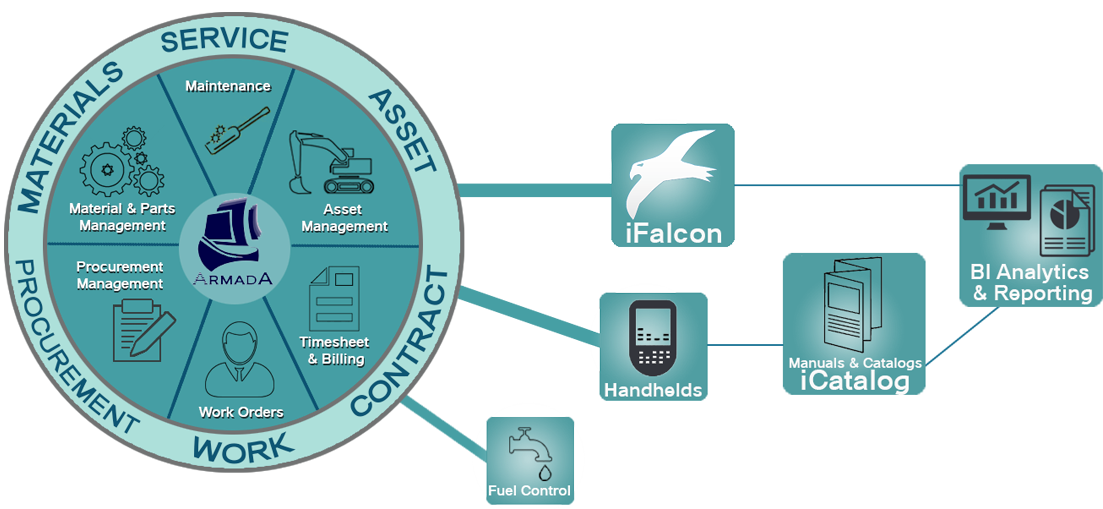

Armada™ is a unique, fully integrated construction fleet management and maintenance solution for IBM® Maximo® for Transportation. Armada™ is an end to end layer-based solution which includes industry focused interfaces to allow maintenance specialists to manage construction equipment and fleet within one system that is tightly coupled to your company’s procedures, best practices and asset strategy. The Challenges One of the major challenges for contractors on the corporate level is how to effectively manage different types of assets, locate them and make the right investment decisions based on reliable, real-time Asset Management information. More than ever before, maximizing the availability and performance of assets while sustaining environmental and safety regulation has become a critical task. On the operational level, fleet and maintenance managers must make immediate and strategic decisions that require effective data analysis capabilities and reporting. They also need Asset Management Information placed into the hands of maintenance technicians and storeroom personnel rapidly.

The Benefits Contractor’s benefits are realized in a very short period of time. Some of Armada’s benefits include:

Reduce Maintenance Expenditure: Armada reduced maintenance expenditure of a major multinational contractor with over $1B of assets, by 15%. Asset Downtime Reduction: Unscheduled downtimes are reduced typically by 25%. Some construction equipment can cause thousands of dollars a day in losses if down. Balanced Inventory of Material Parts and Consumables: Understocking can cause downtimes to extend by up to 45%. Overstocking can cause increases in storage costs and shrinkage. With Armada, the Material Management module balances your inventory. Reduced Staffing Costs: Our customers typically realize up to 10% savings in labor costs due to improved productivity. Keep your staff busy maintaining equipment instead of paperwork and other time wasting tasks. Increase Equipment Life: Well planned maintenance using proper policies and procedures can meet and exceed equipment life expectancy. Safety and Reliability: Equipment which is regularly and stringently checked during maintenance, greatly increases safety and reliability especially in the harsh environments contractors operate it.

Switching from reactive to predictive maintenance Armada® facilitates shifting from reactive to predictive maintenance. The solution can seamlessly integrate with connected equipment using telematics devices, extract performance data and predict potential problems in advance. This helps contractors in managing the maintenance of the equipment in a non-reactive, scheduled approach that minimizes downtime to the lowest levels while reducing idle maintenance resources.

IBM® MAXIMO® is a registered trademark of IBM Inc., and/or its subsidiaries and/or affiliates, in the United States. |