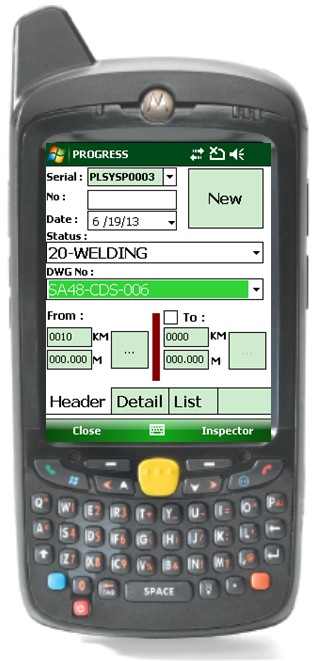

MPCS: Pipeline Construction ManagementMobile Pipeline Construction Management system (MPCM), our flagship solution for managing pipe construction on site, covers all procedural aspects needed for monitoring pipeline progress from delivery, transfer, activity updates to welding reports and QC inspections/Tests. With the advance in technology, our product is ADC (Automated Data Collection) based system giving the capability to operate mobile using varies communication channels such GPRS, EDGE...etc, leveraging for flexible real-time implementations under a diversity of environments. MPCM strives to automate and reduce

paper-work on site and minimize manual entry in return for data

reliability. This is achieved through the usage of mobile barcode

technology, and which is also optionally extendable to RFID. MPCM

can easily integrate with any third-party hardware running Microsoft

Windows Mobile OS such as Motorola mobile computers.

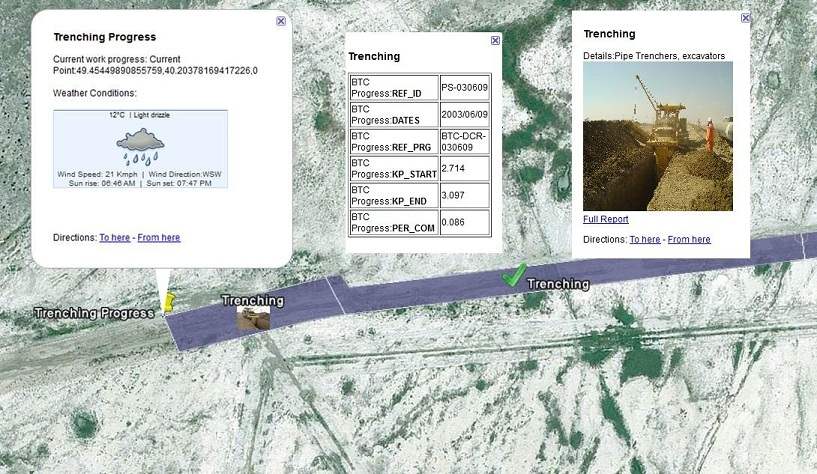

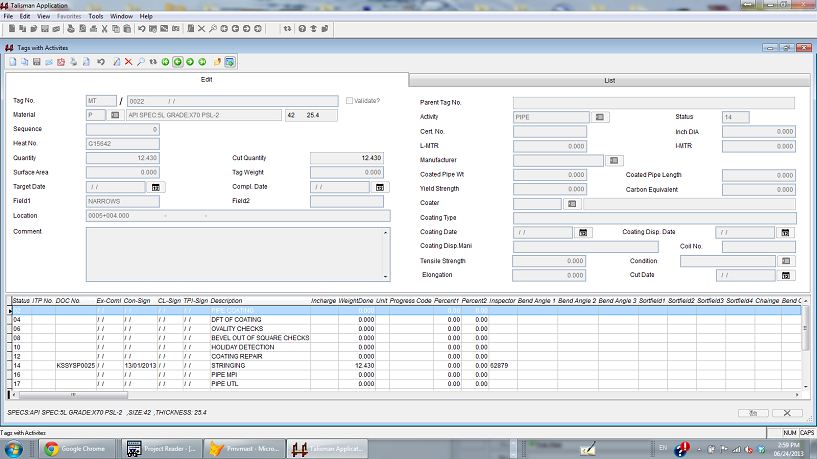

Product DescriptionMPCM is a ADC (Automatic Data Collection) based product built on the Microsoft Windows Mobile platform , and designed to cover all aspects of monitoring pipeline construction going through a standardized cycle of activities such as ‘Stringing’, ‘Holiday Test’, and ‘Bending’ etc. Knowing that each activity used for measuring progress and performance are key to any pipeline construction project, MPCM seeks to optimize on how to best allocate resources and streamline activities. Additionally, MPCM has been enriched with warehouse logistics support for handling the procurement of pipes and equipped with the ability to handle welding procedures for recording and tracing welded joints, along with optional GPS interoperability to fetch the accurate x, y and z coordinates of joints, which could be used to cooperated with GIS. When pipeline activities move from one stage to another, related information gets fed into MPCM by operators or inspectors in-charge of single or multiple activities. The system benefits the project with a history tracked by date and time stamp, which can be used as a good source for planning and measuring progress by line reports on visualy via GIS (including Google Earth). Aside from this, all MPCM users’ activities are tracked and reported immediately if any failure or unusual validation occurs, allowing for swift action to be taken by supervisors and managers. At anytime, MPCM can automatically blog out the current activity of any requested pipe with live information of its physical location either by its coordinates or location range. For repair purposes, MPCM ses either GPS capabilities or kilometer numbering assigned by the surveyors, to maintain the most accurate location for pipes under any activity especially in welding pipes. This is to ensure less time is spent in retrieval, plus it provides a traceable history of the pipe movement. Updating these parameters into GIS, would result in a real-time presentation of progress on site.

Pipeline are effectively constructed by welding a number of pipes together, in which time, safety and quality are key. Maintaining care along all stages in this process is of high importance. Therefore, PMS extends its functionality to assist QC inspectors or engineers with live references or procedures, such as WPS and welder’s qualification,etc. for empowering their field control over welders and to assure welding efficiency. MPCM helps users save money by reducing rework, time and increasing quality.

Windows

Mobile is a registered trademark of Microsoft Corporation in

the United States and other countries. |